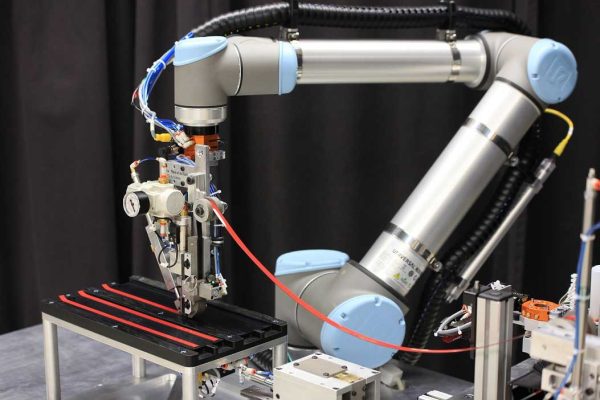

Assembly Application Robot

Make your work easier with assembly robots specially designed for industries that require high precision and repetition!

What is Assembly Robot?

Robotic assembly automation is used especially in industries that require high precision and repetition. Robots can place, fasten, weld, screw in, and other assembly parts using pre-programmed movements.

What are the benefits of assembly robot for your workplace?

Robots minimize the errors that may occur by performing the operations at the same speed and quality all the time. It provides higher quality and more consistent production. It provides efficiency, capacity and cost advantage with the speed it provides. Assembly robots ensure business continuity. Robots can ensure that the 24/7 production process continues under all conditions.

In which sectors and applications it can be used?

Robotic assembly automation can be used in assembly operations such as assembling, screwing, welding, gluing or soldering parts. This application is used in automotive, electronics, medical, aerospace, defense and many other industries. Besides these industries, the assembly robot can be used in textile, furniture, packaging and many different sectors.

What features should you pay attention to when buying?

Before you buy, it’s important to determine what type of robotic assembly automation you need. Repetition period, features of your products, features of your production processes and other requirements should be considered.

The performance of robotic assembly automation is critical to the efficiency of your production line and product quality. Before purchasing, you should get information about the robot’s speed, accuracy, repeatability, height adjustment, connectivity and other features.

What to consider when integrating the product into your system?

During the integration, you must first analyze the needs and make sure that the robot will meet the requirements. The assembly robot you choose must be compatible with your existing system. The characteristics of the systems and other equipment to which the robot will be connected are important for the integration of the robot. The technical competence of the integrator company is important for the correct integration of the robot. The company must be an expert in the assembly, programming and testing of the robot.

Why Exonsys?

As Exonsys, we have cooperated with many global robot companies such as ABB, Yaskawa and Kuka within the scope of our customers’ projects. We can provide physical (wire fence, etc.) and hardware (sensor, etc.) measures. If desired, we can obtain the occupational safety certification of robots with intermediary institutions.