Palletizing and Packing Robot

Increase productivity and efficiency while reducing labor costs in your business by using robotic automation in packaging and palletizing processes!

What is Palletizing and Packaging Robot?

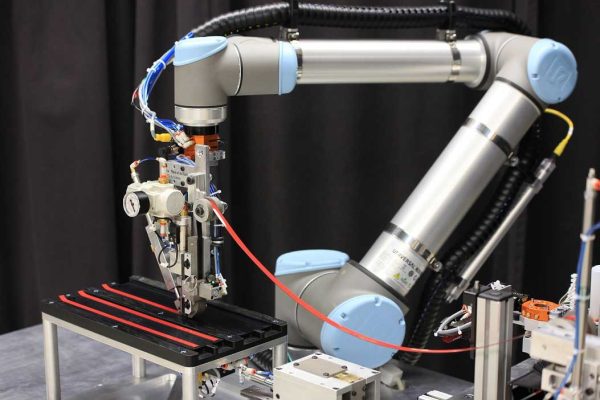

Packing and palletizing robots are automated machines used in industrial manufacturing and warehousing operations. These robots are designed to pack or palletize products according to predetermined schedules. Packaging robots place products in boxes or packages, while palletizer robots place boxes or packaging on pallets in a certain order. In addition, robots can also perform the reverse of the same operations.

What are the benefits for your workplace?

Palletizing and packaging robots increase the production speed of businesses by packing products quickly and efficiently. This helps businesses produce more products and shorten delivery times. Palletizing and packaging robots reduce workload and reduce costs. It also prevents possible health problems due to the repetitive structure of the work done. Palletizing and packaging robots increase the quality of the result by packing the products correctly and in a standard way. This increases customer satisfaction and reduces recycling rates.

In which sectors and applications it can be used?

Palletizing robots; can be used in automotive, electronics, metalworking, food, textile, e-commerce, logistics, and many more sectors. It can be used in all applications where pick and place operation is performed.

What features should you pay attention to when buying?

When purchasing a packaging and palletizing robot, you should pay attention to the features that suit your business needs. For example, you should consider factors such as load capacity, mobility, speed, sensitivity. In addition, gripper choice is an important part of the process.

What to consider when integrating the product into your system?

During the integration, you must first analyze the needs and make sure that the robot will meet the requirements. The robot you choose must be compatible with your current system. The characteristics of the systems and other equipment to which the robot will be connected are important for the integration of the robot. The technical competence of the integrator company is important for the integration of the robot. The company must be an expert in the assembly, programming and testing of the robot.

Why Exonsys?

As Exonsys, we have cooperated with many global robot companies such as ABB, Yaskawa and Kuka within the scope of our customers’ projects. In addition to programming the robot and integrating it into our customer’s process, the required safety in terms of occupational safety in robot projects; We can provide physical (wire fence, etc.) and hardware (sensor, etc.) measures. If desired, we can obtain the occupational safety certification of robots through intermediary institutions.