Material Handling Application

Increase speed, efficiency, quality and safety standards in your production with the material handling application robot!

What is a Material Handling Robot?

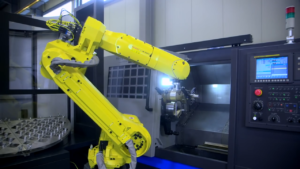

Robotic handling is an automation method that allows materials or parts to be placed automatically into a processing machine, cnc bench, press machine or any line in industrial production processes. In this process, robots place materials into the processing machine at the right position and time, speeding up the work process and reducing human errors.

What are the benefits?

Efficiency: The material handling robot automates handling and placement on the production line, increasing the speed and efficiency of the production process.

Cost: Material handling robots reduce human resource costs.

Quality: Material handling robots increase product quality by ensuring that materials are placed correctly. The precision of the robots minimizes the errors caused by human errors.

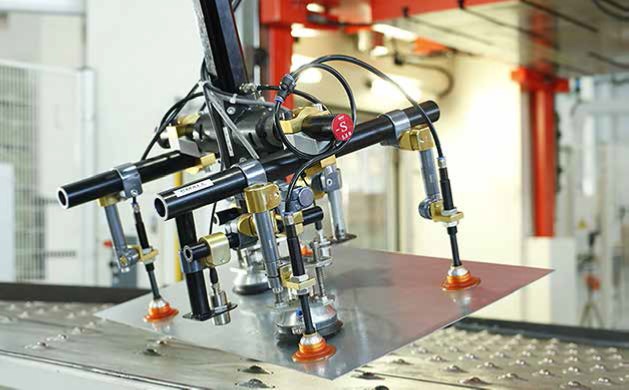

Safety: Handling robots can be used to move and place heavy or dangerous materials. This reduces the risks for users with hazardous materials and increases safety in the workplace.

Continuity: Feeding robots ensure business continuity. Robots can keep the production process running 24/7.

In which sectors and applications it can be used?

Material handling robots can be used in automotive, electronics, metalworking, food, textile, and many more industries. It can be used in all applications where pick and place operation is performed.

What features should you pay attention to when buying?

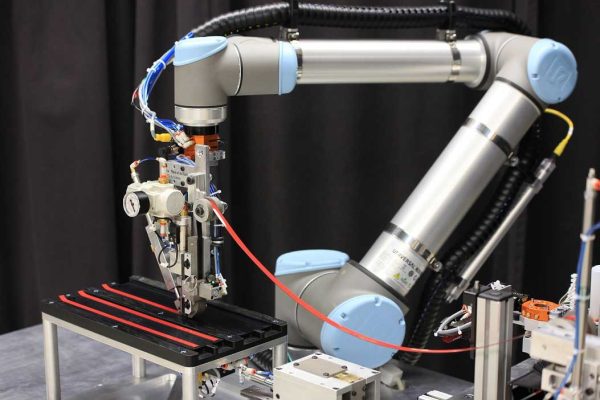

When purchasing a robot for material handling, you should pay attention to the features that suit the needs of your business. For example, you should consider factors such as load capacity, mobility, speed and sensitivity.

What to consider when integrating the product into your system?

During the integration, you must first analyze the needs. The feeding robot you choose must be compatible with your current system. The characteristics of the systems and other equipment to which the robot will be connected are important for the integration of the robot. The technical competence of the integrator company is important for the integration of the robot. The company must be an expert in the assembly, programming, and testing of the robot.

Why Exonsys?

As Exonsys, we have cooperated with many global robot companies such as ABB, Yaskawa and Kuka within the scope of our customers’ projects. In addition to programming the robot and integrating it into our customer’s process, the required safety in terms of occupational safety in robot projects; We can provide physical (wire fence, etc.) and hardware (sensor, etc.) measures. If desired, we can obtain the safety certification of robots with intermediary institutions.